Propane DeHydrogenation (PDH)

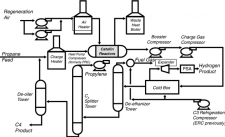

Propane dehydrogenation (PDH) is the process that converts propane into propylene (propene) and hydrogen as a by-product. The process consists of a reactor section, product recovery section and a catalyst regeneration section. Hydrocarbon feed is mixed with hyrogen-rich recycle gas adn is fed into a heater to be heated to over 540 degrees Celcius (1000 F) and then enters the reactors to be converted at high mono-olefin selectivity. Several interstage heaters are used to maintain the reaction through supplying heat continuously, since the reaction is endothermic.

The reactor effluent is compressed, dried and sent to a cryogenic separator where hydroen is recovered. The olefin product is sent to a selective hdrogenation process (SHP) where dienes adn acetylenes are saturated to mono-oelfins. The propylene stream goes to a deethanizer where ligh-ends are removed prior to the propane-propylene (P-P) splitter.

Propylene is used mainly to produdce polypropylene plastics for injection molding and fibers and for manufacturing cumene (used in phenol production).

View All Manufacturers