Power Industry and Cogeneration

Power generation in the industry can be based in various technologies ranging from engine driven generators to larger gas or steam turbines. More recently, cogeneration or ‘Combined Heat and Power’ (CHP) systems are seen also being employed, providing a more efficient way to simultaneously generate both electric power and useful thermal energy (for heating or cooling) from a single fuel source. Unlike processes that generate only electrical energy, a CHP system, by utilising also waste heat, by producing simultaneously electricity and thermal energy, maximises the conversion of the potential energy in the fuel, into useful energy, usually at or near 90% overall efficiency.

CHP facilities are most amenable to industrial users with heat or steam demands, such as refineries and process plants, with the majority of industrial CHP capacity found in the chemical, petroleum refining, and pulp and paper industries. Food and primary metals industries make up most of the remaining CHP, though cogeneration applications can also be found in the commercial sector, for heating and air conditioning in domestic and public buildings.

LPG powered CHP systems are gaining rapidly importance for their ability to operate with far greater efficiency. They also produce lower carbon emissions than conventional systems, in addition to being cost effective and easily transportatable to where power is needed. LPG fueled engine cogeneration systems are also used for CO2 fertilization in greenhouses. Trigeneration systems, combining generation of heat, cooling and power are also starting to be used.

Applications

Power/Electricity Generators

Combined Heat and Power (CHP)

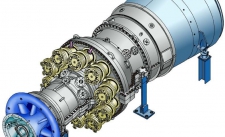

LPG Gas Turbines

LPG Microturbines

Large LPG Gas Engines